Target Fabrication Group is set up to work closely with the user community to provide delivery, characterisation and support of high specification micro-targets. The group of engineers, physicists and materials scientists provide a variety of solid target solutions for the two main laser systems on site: Vulcanand Astra Gemini

What is a Micro-Target?

It is difficult to give a general definition of a micro-target. It’s loosely described as a solid geometry at the interaction point of a high power laser system. The composition and design is dependent on experimental aims and there therefore is a great deal of variety from experiment to experiment.

- They can be made of a range of elements or compounds in a wide variety of combinations, but typically ~ few nm to few mm in scale size

- Microtargets can (uncomfortably) be put into two broad categories: 2D (thin film) and 3D (often complex), but with many exceptions

- 2D microtargets typically have a thin film component from a few nm (10’s atoms) to many mm thick. Thickness, roughness and structure need to be precisely measured. Films/foils often need to be supported on a mount

- 3D microtargets are often made from assembled microcomponents (which usually need bonding). Components usually need to be assembled to 2 micron and 0.1 degree accuracies

- Micro-Targets are often shot in clusters with precisely defined distances and angles between individual components.

- All to be characterised fully before the shot because microtargets are destroyed every shot

|

|

|

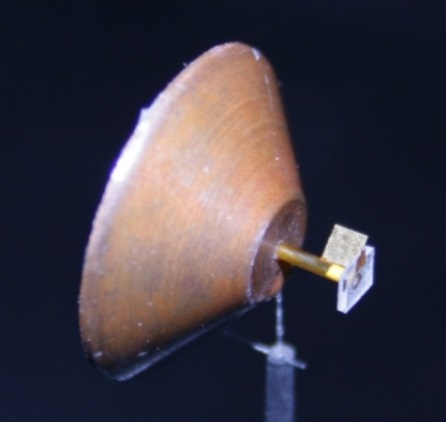

3D geometry

This target is a combination of polymer foam, thin film coating and micro-machining capabilities |

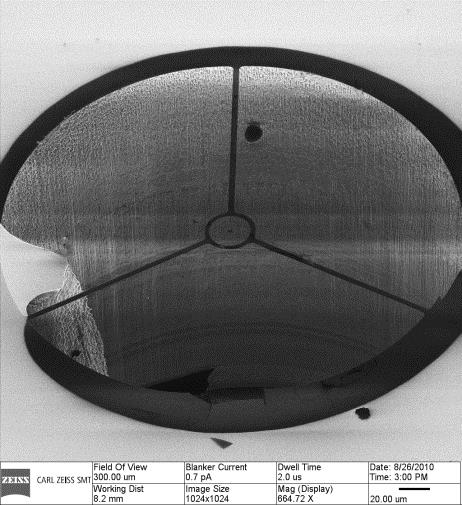

MEMS target

The smallest feature size on this spoke target is 1um. Produced by silicon wafer based etching technology |

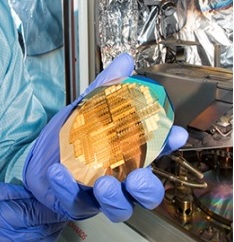

Thin film coating

Approximately 100 nanometres of Gold

coated on a silicon wafer. Deposited by plasma sputtering

|

Target modifications are possible during experimental campaigns enabling experiments to maintain fluidity with the limited time that is available on the facilities.

The Target Fabrication Group has extensive expertise in the areas of:

Research and Development projects are on-going into novel target designs and micro-assembly techniques to be able to deliver targets for the future high power lasers.

Staff list

Target Fabrication is committed to providing laser microtarget development and fabrication to the highest standards, and meeting of exceeding customer requirements.

|

The Target Fabrication Laboratory

|

© 2016 Science and Technology Facilities Council - All Rights Reserved.