Join us once again to find out how the year has flown by with some of our placement students as they share their thoughts and experiences on a very unexpected placement year. Here's a link to the beginning of the year interviews we did with the students.

Student Profiles:

- Daniel Bedilu was a laser-plasma physicist for Vulcan and will return to the University of Bath to complete his Integrated master's in physics.

- Viviene Marie Dela Cruz was a development scientist for high energy laser at CALTA and will return to the City, University of London to finish her Electrical and Electronic Engineering degree

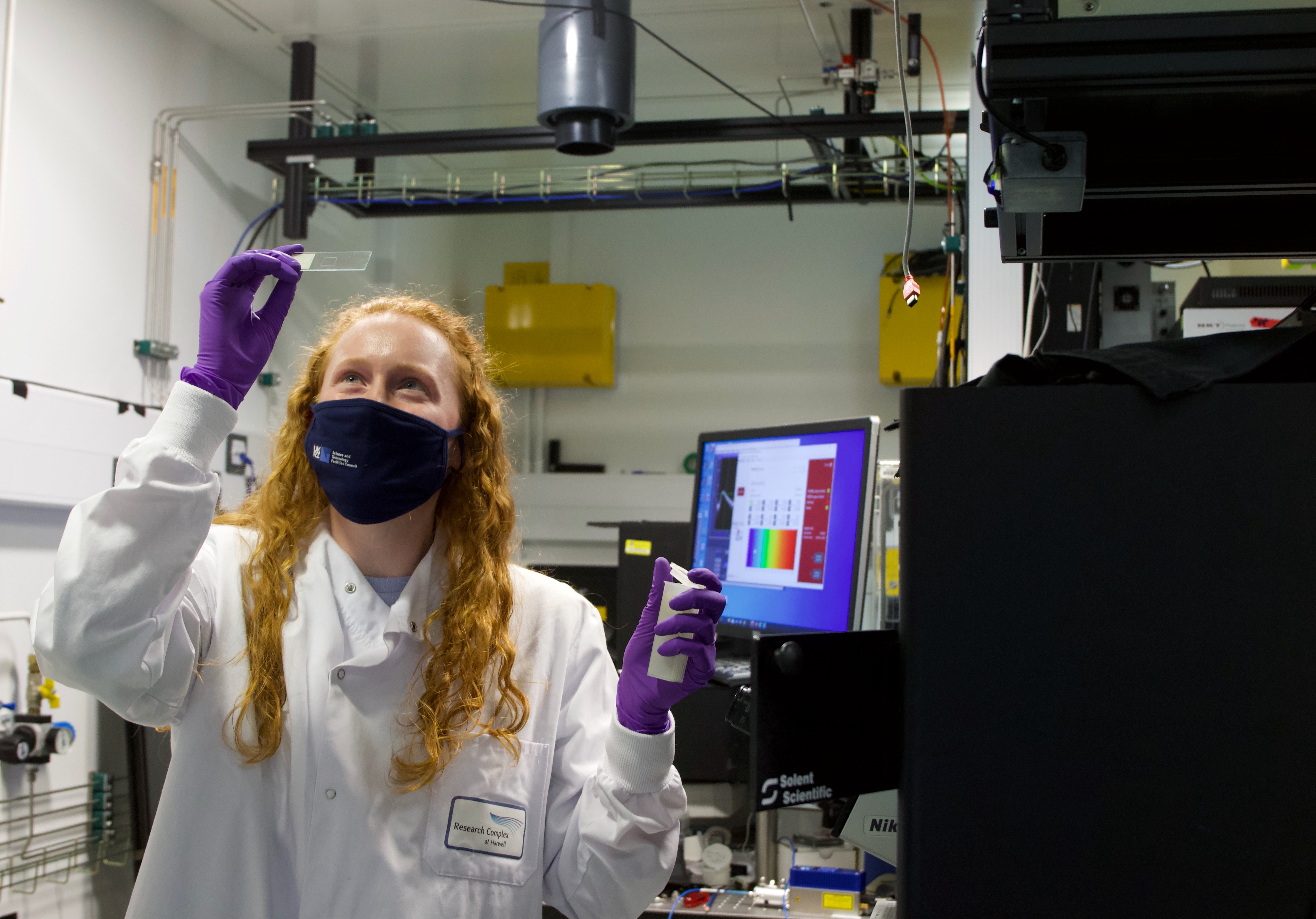

- Ellen Clancy completed her 2nd year at the University of Birmingham in Biological Sciences and joined the CLF on a project to study the effect of induced DNA damage through lasers and its repair process at the OCTOPUS Imaging Cluster.

- Tuege Neumann is going back to finish his Integrated Masters in Mechatronic Engineering at the University of Manchester and worked with the target fabrication group as a laser target engineer.

Daniel Bedilu

What has been the highlight of your time at STFC?

Daniel: Assisting with the experiments has been a big one for me because I've gotten to work with user groups and see the science happening up close. Hopefully, in a couple of months' time, I will see a paper come out, and see the work I did that ended up on the publication. With lockdown easing, meeting some of the other placement students has also been a highlight.

Viviene: I actually have a couple of highlights from my placement year. My main one is developing a diagnostic line to detect damage occurring on laser optics, which acquires images and analyses them three to four times quicker compared to the previous systems. It's extremely rewarding as I had not worked with lasers and optics before my placement, and it turned out to be a successful system that I set up and developed myself.

I think my second highlight has been meeting like-minded people at STFC. It's a very open and friendly environment, which makes me feel like I found my crowd of people. I've also been able to take part in loads of outreach activities where I've been involved in inspiring the next generation of scientists and engineers.

Ellen: I think the big one for me is being able to network with loads of different people from public-facing organisations, like the Rosalind Franklin Institute (RFI) and Public Health England. The work I got to be a part of with the RFI was especially exciting since it was on the forefront in doing some of the COVID research.

Tuege: The project I worked on was quite independent, so seeing and meeting more like-minded placement students has been a highlight for me. Another highlight for me has been automating assembly processes which has made a huge impact for the target fabrication group.

Viviene Marie Dela Cruz

What's the most useful thing you've learned during the placement?

Daniel: Learning how things operate in terms of scientific collaboration, but also seeing how different division functions work has been interesting. Before my placement, I would have never considered the collaboration that takes place between areas like Target Fab or Engineering to carry out an experiment. Learning about the synergistic effect the different areas have has not only made me appreciate the research at the facility, but also the wider research field in general.

Viviene: I think time management, goal setting, and prioritisation are the top things I've learned. Learning these skills has been useful because they have helped me focus and gain insights into areas like photonics, which I had very little to no experience with before my placement, but am now considering as a further study option. These skills are transferrable and will help me for my future career prospects.

Ellen: Understanding the different stages of experiment planning has been the most useful thing I've learned. There're so many nuances that go into planning, executing and delivering an experiment that I wouldn't have had an appreciation for at university.

Tuege: I think the experience I have gained in industrial automation has really been invaluable to me. Understanding all the different concepts that play into setting up a system that is reliable, accurate and complies with industrial and safety standards has given me a real head start for starting my career as a mechatronics engineer.

Has the placement year been what you expected?

Daniel: I think it's been better than what I expected. I came in with the idea that the placement would have been very structured and you get assigned work. Instead, I had loads of flexibility during the year to work on loads of different projects. At one point in my placement, I was working on analysing magnetic fields in spectrometers. Instead of carrying on in the direction that the previous placement student was doing, I was allowed to independently build the project to focus on a simulation approach and optimize the design of the spectrometer.

Viviene: Before starting my placement, I assumed there would be a very rigid structure in place. I found the workplace and routines rather flexible and more welcoming. One of the things I appreciate is how much learning is prioritised and encouraged. Working at CLF, it's evident that it's not just about displaying your skills, but also honing your skills to help others.

Ellen: I feel like it's been different to what I expected – especially getting used to working in the labs with social distancing and other restrictions. However, I'm appreciative of how accommodating the people around me have been.

Tuege: I think I expected to learn a lot about how things are produced commercially, but I never realised what working at a national facility would entail. Doing the year in industry has also given me a more holistic insight of what goes on at different departments and how people that have non-scientific roles are involved in running it.

Ellen Clancy

What's been the most exciting thing you've gotten to work on/accomplish?

Daniel: I worked on improving a diagnostic, called a Thompson spectrometer. Instead of using an image plate on the spectrometer, I worked on using a scintillator as a detector. That was exciting because I got to test and improve the design, and the best part was that my design was used on Gemini.

I expected to stay back and not be able to do much with my design as a placement student, however, it was rewarding to see my work being adopted on one our laser systems.

Viviene: Definitely, optimising the beam diagnostic line, so it's much quicker and in real-time. I designed, programmed, and assembled it on the optical table. The previous system was running at 20 frame per second (fps), and because of the work I did it reaches 88 fps.

Ellen: I think the prospect of working on an experiment with a manuscript coming out in a couple of months that might have my name on it is exciting.

Tuege: I think my project that has been focused on assembling a target array without human intervention using a robotic arm has been my biggest achievement. Working on this project independently has meant that I have been able to provide the target fabrication group with a completely new capability, which will be necessary in the next few years in producing targets for EPAC.

Tuege Neumann

What advice would you give to other placement students?

Daniel: Give things a go. Sometimes people will ask “Is anyone around to help out?" Even if you're unsure whether you want to do something or if you're capable, do it anyway. You might enjoy what you're doing, or you'll end up learning something new.

Viviene: Be curious. No matter how big or small – if something intrigues you ask about it. There are so many scientists and engineers around you so even when you ask the same question you're bound to get loads of different perspectives.

Ellen: Get involved as much as you can. Whether it's with all the different projects or all the different people in your team because there's so much interesting things going on at STFC. Another thing would be to ask as many questions as you can because it's an amazing chance to find out what your colleagues are doing and seek out new opportunities.

Tuege: You're at a level in your education where employers hire you to help solve challenges, which means that when you join a department like the CLF, they are enlisting your help as someone that's part of the team. Even if you're a student you shouldn't underestimate what you bring to the table, instead use it as leverage to take advice and bring in fresh perspectives.