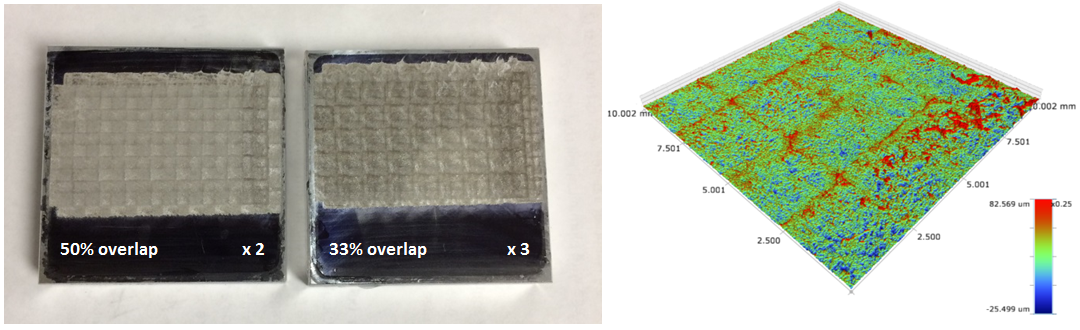

Laser shock peening is a non-contact surface treatment

that can improve the mechanical properties of metallic alloys through

the introduction of deep compressive residual stress in excess of 2 mm beneath

the treated surface. A nanosecond pulsed laser is targeted at the component

surface creating energetic plasma which sends a shockwave deep into the

material. This shockwave can be amplified by submerging the sample in water to

confine the plasma and optional ablative coatings can also be used to enhance

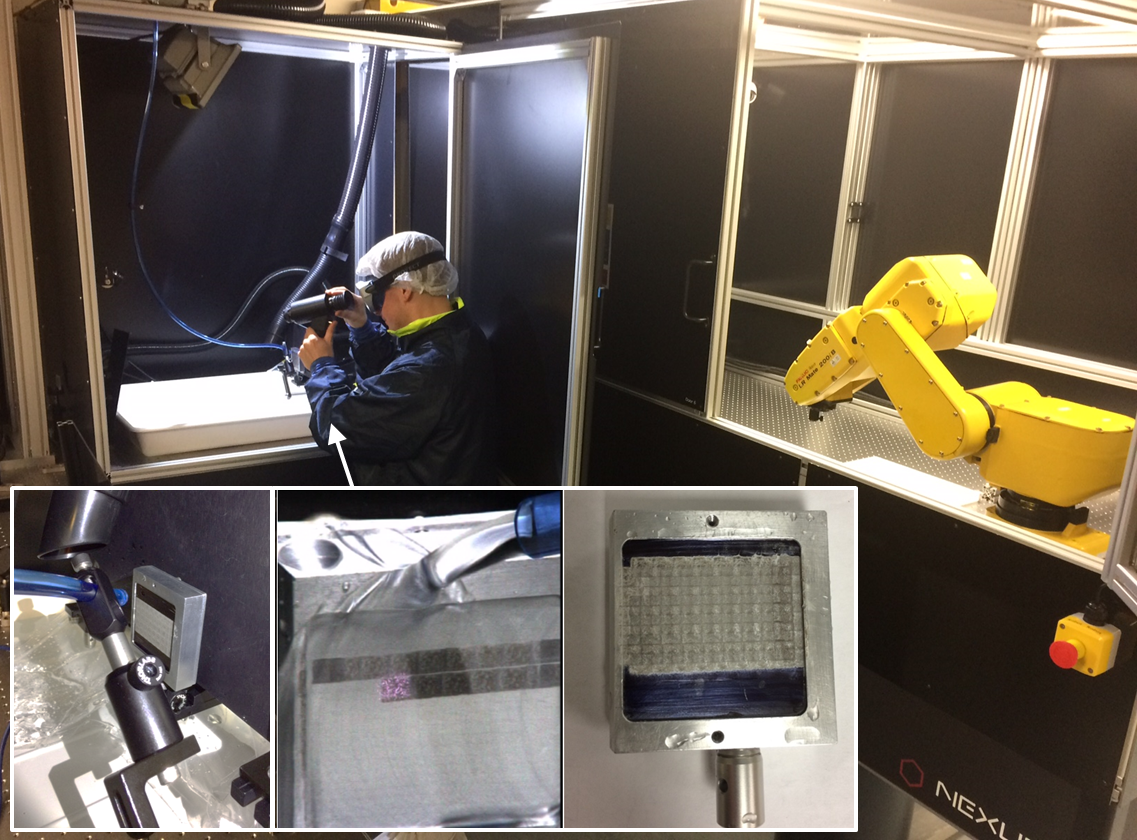

energy absorption. A new laser shock peening platform has been commissioned at

the Rutherford Appleton Laboratory’s Central Laser Facility based upon our

in-house DiPOLE laser architecture: A 10J, 10Hz, nanosecond pulsed, cryogenic

gas-cooled Yb:YAG laser. The flexible new system offers full control over the

laser peening parameters enabling optimised treatments tailored to specific

materials and their applications.

High value sectors such as aerospace and nuclear power

generation have slowly adopted laser shock peening as a specialised tool for

improving performance in critical components. In the nuclear industry,

protection of pressurised water reactors against stress corrosion cracking is

of fundamental importance to ensure safe operation over increasingly long

reactor lifetimes. Pressure vessel steels are chosen for their stable

microstructures at elevated temperatures with internal stainless steel cladding

for improved corrosion resistance.