Target Fabrication contributes to materials development with a newly refurbished dedicated materials laboratory. Research and development projects into novel materials including low density polymer foams, ultra-thin polymer films, electrodeposition, and aerogels are the main priorities.

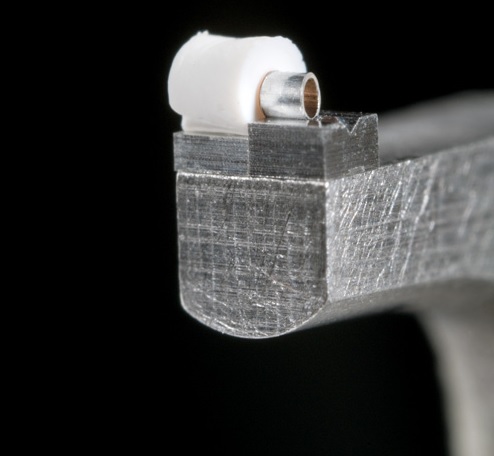

Materials targets fall within microtargetry allowing the manufacture of targets in the millimetre scale in at least one dimension, smaller in others.

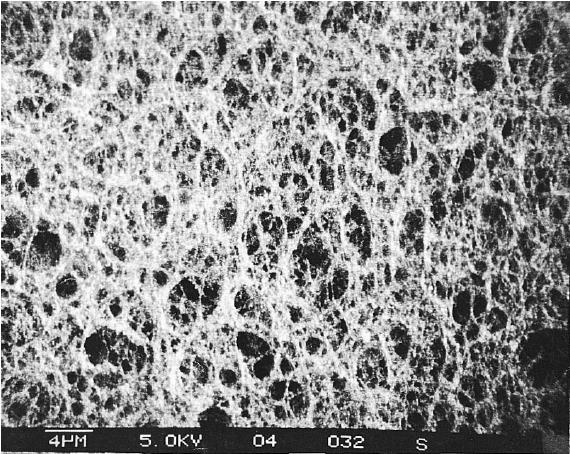

Polymer foam capabilities include production of TMPTA polymer foams from 1000mg/cc – 5mg/cc. Foams are made inside target geometries as the delicate structure does not allow for intra- or post-production machining or target assemblies.

Ultra-thin Formvar films are produced through dip or spin coating. Film thickness, or thinness in this case, is dependent on a number of factors including solution concentration, and spin/dip speed. Achievable uniform thicknesses range from 10nm – 100nm.

Electrodeposition capabilities include the deposition of gold on to aluminium substrates. Aluminium substrates are machined to the desired geometries prior to gold electroplating. Gold plating in this way has allowed for the production of uniform thickness across a patterned surface.

|  |

| Foam as part of a 3D target |

Structure of a polymer foam under a Scanning Electron Microscope

|