The CLF mechanical workshop is equipped with manual machines, 2D CNC and 3 axis 3D CNC machines enabling the team to manufacture bespoke components required for experiments and development projects

Expert 2D CNC machining

The workshops 2D CNC capabilities can machine plastics, metal foils and sheet from 25µm to 3mm. It is frequently used to prepare film for proton beam diagnostics and foil shields for experiments in batch quantities. We also produce complex 2D profiles required for items such as engraved labels or chopper discs. The laser etching machine adds capability for identification labels used on items such as motors to enable a bar code to be scanned into the drive system.

Expert 3D CNC machining

The workshops 3D CNC capabilities are 3 axis XYZ and are used for producing complex components rather than batches of components. The 3D CNC compliments the manual machining capabilities of the workshop, which includes lathes, mills, bandsaw, grinding wheels. The expert machinists can manufacture a range of materials, sizes and complexities.

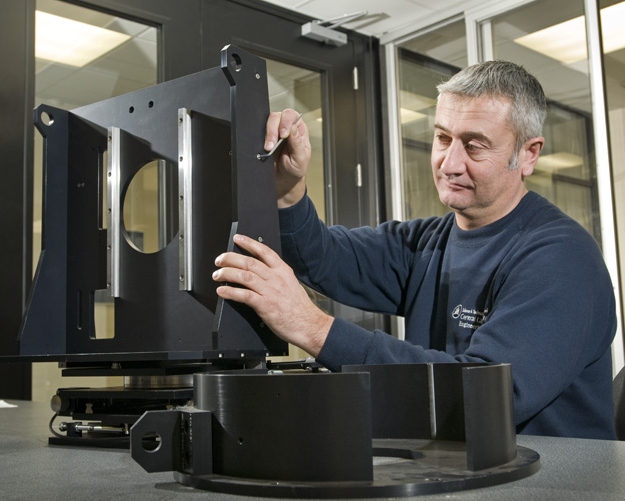

Mechanical assembly

The assembly area is used to assemble a wide range of equipment from motorised mirror mounts to interlocked enclosures.

Installing gas systems

The team installs gas systems, water systems, vacuum systems, optical tables and interlock enclosures across the CLF to improve the capabilities and reliability of the facility. The team also has expertise in lifting and register all the lifting equipment for CLF.

Expertise in specialist lifting

The team supports the experiments during operational periods, but has a primary role of maintaining and developing the core infrastructure of CLF labs, plant rooms and facilities. The workshop team are heavily involved in development projects and have to work within the tight schedules of shutdown periods.

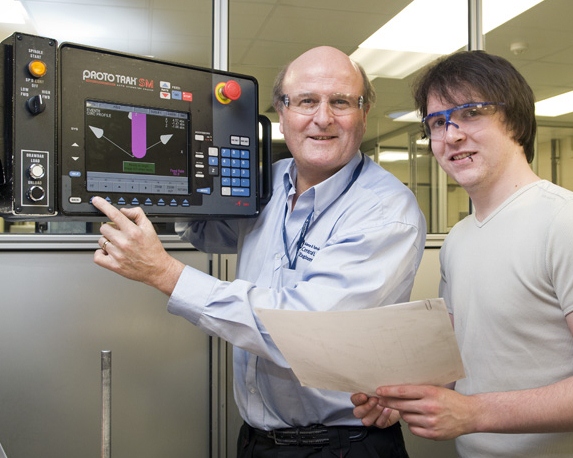

Apprenticeship training

The mechanical workshop is actively involved in the apprentice training scheme at the Rutherford Appleton Laboratory passing on knowledge and skills to the younger generation.