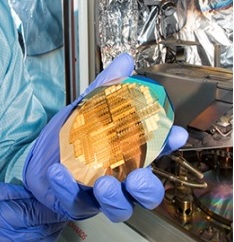

Target Fabrication has the capability to deposit a variety of thin film materials from tens of atoms thick up to many microns.

Capabilities include:

Thin Film Gold Coating

Thermal Evaporation

Vaporisation and condensing of a material under vacuum by way of resistive heating. Ideal for low melting point metals such as Aluminium in thicknesses 10nm-1000nm

Electron-Beam Evaporation

Principally the same as Thermal Evaporation, however the material to be deposited is heated directly by a focused beam of electrons. This allows for deposition of exotic materials with higher melting points such as Gadolinium, Zirconium and Potassium Bromide.

Plasma created by Splasma Sputter Coating plant

Plasma Sputtering

Particles are ejected from a solid target by way of bombardment by energetic Argon ions. Target Fabrication has the capability to do co-deposits, two separate materials deposited concurrently. This allows for two contrasting Z-materials to be equally dispersed throughout a material

Parylene Coating

Plastics can be coated by way of Chemical Vapour Deposition. Produces a thin a low atomic number material (hydrocarbon) that is strong at thicknesses as low as 100 nanometres. Chlorinated plastics can also be coated by this technique.

Diamond-Like Carbon (DLC)

An amorphous carbon film with the material properties of diamond. The resulting coating is excellent for ultra-thin laser targets as thin as five nanometres.