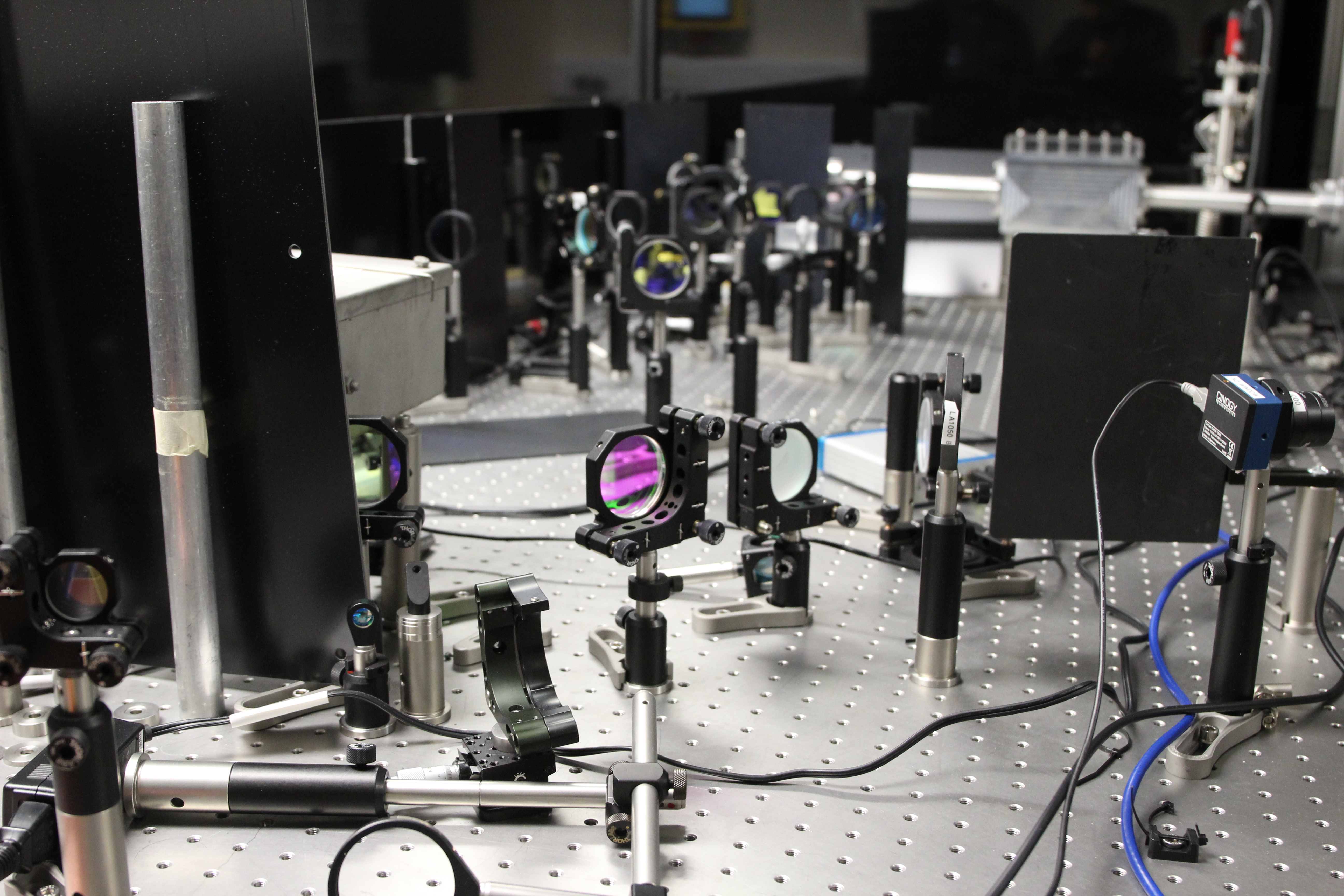

DiPOLE is a scalable diode pumped, cryogenic gas cooled multi-slab ceramic Yb:YAG laser system, capable of generating temporally shaped pulses (2–10 ns in duration) at 1030 nm wavelength up to 10 J at 10 Hz. The laser shock peening platform was commissioned at the Rutherford Appleton Laboratory's Central Laser Facility utilising the DiPOLE laser system.

Saumyabrata Banerjee and Jonathan Philips in the peening lab

Laser Shock Peening (LSP) is a technique used to improve material performance through the introduction of compressive residual stresses, strain hardening and reduction in fatigue fracture. High value sectors such as aerospace and nuclear power generation have slowly adopted laser shock peening as a specialised tool for improving performance in critical components. For example, in the nuclear industry, protection of pressurised water reactors against stress corrosion cracking is of fundamental importance to ensure safe operation over increasingly long reactor lifetimes. LSP is used to improve the strength and resilience of these pressure vessels. Turbine blades in aircraft's high-performance engines are hardened using laser shock peening to improve component reliability and longevity. This technique (LSP) was successfully demonstrated by the laser team and collaborators in the CLF's DiPOLE laboratory.

In a recent experiment led by Dr. Saumyabrata Banerjee, acoustic signals produced during LSP of aluminium, titanium and stainless steel alloys were recorded and analysed. The sound generated by striking an object has been utilised as an indicator of thickness, hardness or existence of defects in a material such as concrete in the construction industry. Analogously, laser shock peening process can be compared to “hammering" a sample with a laser pulse, and the acoustic signal generated can be used as a probe signal to define the quality of the process.

Photograph of Peening Lab Laser

A clear trend emerged when the acoustic signals from LSP process were analysed using a method described in a recent publication [1]. Dr. Saumyabrata Banerjee and co-workers benchmarked the analysed acoustic signals with the conventionally obtained values of residual stresses by incremental centre hole drilling technique (ICHD), and found that a qualitative evaluation of residual stresses of the peened sample is possible by just listening to and analysing the acoustic signal generated during LSP process. This research on the acoustic signature of laser shock peening, described in detail in ref [1] can be utilised to ascertain successful peening in materials and have the potential to be used as an in-situ, inexpensive and in-line process monitoring diagnostic for industrial scale LSP processes.

Link to video: https://www.clf.stfc.ac.uk/Pages/Laser-Shock-Peening.aspx

1) Saumyabrata Banerjee, Jonathan Phillips, James Nygaard, Paul D. Mason, Klaus Ertel, Mariastefania De Vido, Thomas Butcher, Steph Tomlinson, Jodie Smith, Ric Allott, Chris Edwards, and John Collier ; “Acoustic signature of laser shock peening for a qualitative evaluation of residual stresses" Appl. Phys. A (2019) 125: 571. https://doi.org/10.1007/s00339-019-2869-1