Laser Shock Peening

Laser Shock Peening (LSP) is a technique used to increase a materials resistance to repeated exposure to external stresses (fatigue life) and improve the wear resistance of materials, which is important in industry for improving the operational life of systems. The technique uses a high-energy short pulse laser (like DiPOLE10) focused on the surface of the metal to form a plasma, which is confined (normally using water). This process results in compressive residual stresses being introduced into the sample, which are part of what improve the fatigue life of the sample.

Tungsten has the highest melting point of all metals, making it excellent as a divertor in a tokamak for extracting heat to minimise plasma contamination and protect the tokamak structure from excessive damaging heat. However, all of these “stresses" weaken the tungsten over the operational life of the tokamak, eventually resulting in it failing and needing replacement. Therefore, improving the fatigue life of tungsten will significantly impact the lifetime of tokamak-based fusion reactors and operational costs for them in the future, an important step towards future conversion of research tokamak fusion reactors into viable industrial and commercial power options.

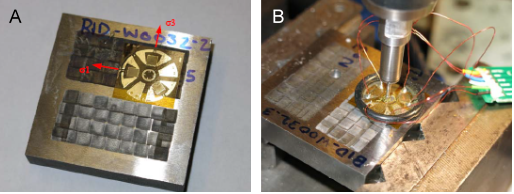

Dr Saumayabrata Banerjee and Dr Jacob Spear from the CLF worked with a CLF-CALTA industrial placement student, Mr Patrick J. Dalton from Queen's University Belfast, to perform LSP experiments on tungsten to determine if LSP under ambient conditions could introduce compressive stresses in tungsten. The group determined that not only did performing LSP on tungsten produce high compressive stresses, but they also discovered circularly polarised light incident on tungsten enhanced the compressive stresses in one direction compared to when LSP was done with non-circularly polarised light. When compared to aluminium (a softer material), they validated that this dependence on circularly polarised light is unique to tungsten (and potentially other hard materials), making it an important parameter to consider when performing LSP in the future.

Overall, the research was conclusive in finding that using LSP on tungsten could increase its fatigue life and be a beneficial technique for increasing the operational life of tokamaks and other devices that utilise tungsten for its high heat tolerance and other properties.

Find out more by reading the publication.